Fayble Design

I started Fayble Design with my friend Stephen Skilbred to bring affordable custom furniture to the masses. We saw that there were no good options available to buy simple, but custom furniture. The normal process for buying custom furniture is working directly with a furniture builder, which usually takes 3-6 months (even for something simple) and costs thousands of dollars more than non-custom furniture.

Our vision was to create a vertically integrated furniture company. The customer would order on our website, we would manufacture the furniture using CNC equipment, we would ship the furniture, then the customer would assemble the furniture using simple instructions.

Manufacturing the product ourselves was critical to our value proposition, since it is the only way we could deliver custom furniture within 1-2 weeks. We couldn't afford to buy "real" CNC equipment, so we built our own. We built a full size 4'x8' CNC Router. With this router, we were able to cut plywood, particle board, and aluminum sheets with very little human effort.

We encountered a large number of challenges throughout the process, but we were able to create a minimum viable product as described. We never launched our service to the public mostly due to a lack of capital, but we may continue with the project in the future.

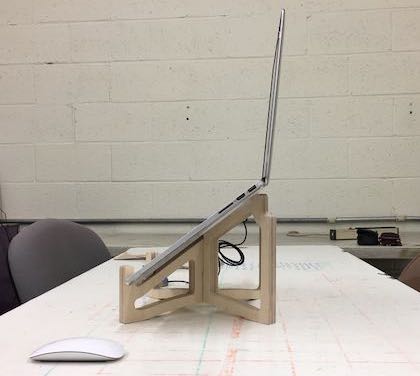

As we experimented with furniture manufacturing, we built a number of pieces of furniture for friends and family, including the tables shown on the left. We also experimented with a number of other smaller products that had similar customizability requirements. This included the laptop stand and the drawer organizers shown on the left.

I developed our website from scratch using a variety of technologies including threejs and Vuejs. The furniture website is available to view at faybledesign.com/furniture

I also developed a website for our drawer organizer product, which is available at faybledesign.com